Babu Paul, Director BRiQ MSS

” Om.. Asato Maa Sad-Gamaya

Tamaso Maa Jyotir-Gamaya

Mrtyor-Maa Amrtam Gamaya

Om Shaantih Shaantih Shaantih (1)”

– Upanishad

A prelude

When I was functioning as Chief of Quality in in an Air Force Overhaul Division, I decided to pen down an article on my view of “Quality Assurance” some day. I start this sojourn with a prayer on my lips. “Oh God… give me strength. Lead me from darkness to light. From ignorance to knowledge.”

Quality in everyday life

We all have different views about Quality. Quality Gurus taught us that it is

- Conformance to specifications.

- The degree to which a product or service meets the needs of the customer.

- Uniformity around a customer defined target.

- Exceeding customer expectations.

I agree to all of them. I am sure you also would agree to these definitions. Then … why does our Reparable, Systems and aircraft fail in the operational units after we do the overhaul or repair?. Why do we face Production Hold Ups(PHUs)?.

Be the God of your Quality

I titled this article as ” A pilgrimage to perfection”. A pilgrimage is a journey or search of moral or spiritual significance. Here… I want it to be a metaphorical journey in to our own beliefs. A belief that ” I am the one who assure the Quality of my work. I will leave no stone unturned and I defy all limitations imposed on me. I shall be the god of my action”. Thus, be the true believer of advaitham, a Malayalam word for non duality. A faith that the abode of god is within the mortal self.

When I was interacting with the young technicians of my division, I often used to tell them that Quality Assurance can only be complete when we have no Quality Assurance Section(QAS) staff to police their actions. QAS inspectors often have limited knowledge and lesser skill level than the technician who works on a test bench producing a limited range of products. Then, where is the question that QAS assures your quality. “Quality needs to be assured by each individual who adds on to the value chain. A logistician who procures the spare, the administrative staff who provides the optimal environment, the top management who ensure your morale and the technician who perfected the art. Like Lord Vishvakarma the architect of the universe, you would strive for Quality in your work.

Journey to the Abode

Quality does not happen as serendipity, “a happy accident” or “a pleasant surprise”. Each element needs to follow “Plan-Do-Check-Act” (PDCA) Cycle . So… what do we do?

- We learn what we have to learn. This is a continuous process.

- We do it again and again till we reach perfection when we are confident to assure the Quality of our own work. After that we would achieve six sigma and much more.

- We reach out to others who can provide us help, guidance and wherewithal.

We decide our destiny. Each day must be an incremental improvement from previous day. A continual improvement of our process which would culminate to better product and higher customer delight.

Failure is an opportunity, not the end of the road

A young Corporal of my depot once asked me in my Lean Management lecture. “Sir,… When a reparable fails during Functional Test(FT), Is it not a waste…?”. I said “Yes…waste of rework as listed in seven types of wastes . And no, since it is a great opportunity to obtain inputs to perfect your process and improve the product”.

Reliability of a product

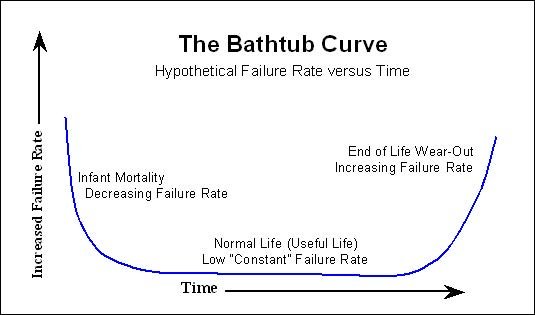

- The first part is a decreasing failure rate, known as early failures.

- The second part is a constant failure rate known as random failures.

- The third part is an increasing failure rate known as wear out failure.

The important information of failure data during all three phases are so vital that it cannot be ignored. The inputs we receive from field units through Defect Reports (DRs), Premature Withdrawal Reports (PWRs) and complaints/feedbacks are valuable data to study Defect Trends. Defect Trend Analysis (DTA) is our first step in Reliability & Maintainability (R&M) studies which would give insight to improve the quality of our products.

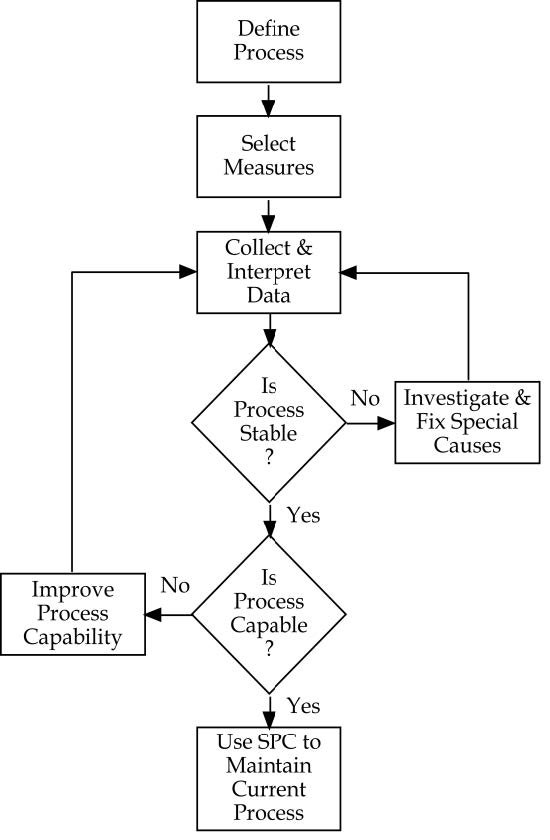

Every individual with professional pride, ego and faith in self have to embark on the path of discovering what is causing failure after his accomplishment of task. I cannot chart a path for you. You have to find it out yourself. A guiding model is provided to you in the flow diagram of Quality Improvement Model .

The purpose of the road map is to provide a sequence of steps to improve your process so that our customers would benefit the highest quality and value. Your steps are

- Defining the process.

- Selection, measurement, collection & interpretation of data.

- For a process found not stable investigate the root causes and fix them.

- For a stable process check to see the process capability. Improve it if found not satisfactory.

- For a stable and capable process use Statistical Process Control(SPC) to maintain the current process.

A faith redefined

Quality should be a junoon for you, an obsession… a faith. It would redefine the world around you. Your quest for improving your own standard each day through collecting the failure data and analysing the Failure trend is the first step to be taken. Improve your process with the knowledge acquired from the DTA, customer feedback and Original Equipment Manufacturer (OEM) manuals. An improved process would improve the quality of product and Quality of Work Life (QWL). This is certainly going to delight the end users. So what are you waiting for?. Without delay, embark on your Pilgrimage to Perfection.

(1)

Translation of sanskrit poem Asatoma….

Om… Lead us from unreality of Transitory existence to the reality of self.

Lead us from darkness of ignorance to the light of spiritual knowledge.

Lead us from the fear of death to the knowledge of immortality.

Om Shanti….Peace….Peace.

(Article was published in IAF Maintenance Journal)

Comments are closed.